Introduction:

This hydraulic type briquette machine includes four parts: briquette machine, PLC (electric control cabinet), hydraulic cylinder and outlet belt conveyor.

This hydraulic type briquette machine includes four parts: briquette machine, PLC (electric control cabinet), hydraulic cylinder and outlet belt conveyor.

On the basis of mechanical punching briquette machine and hydraulic tablet press machine, through two years intense research and countless experiment, we invent this hydraulic machine, which can make up for a lack of ordinary briquette machine.

(1) It has larger pressure, also this pressure can be adjusted according to different raw material.For example, some customers want to get better quality barbecue charcoal (small density, strong, hard and not easy broken), so they adjust pressure large.

(2) Height become higher, this machine press 13cm height is no problem.

(3) It’s more convenient to maintain, because this machine no easy broken parts.

(4) Simple operation, it has automatic and manual operation two kinds, you need press button step by step.

Finished products :

We can customize molds according to different customers demands.Because pressure is so large, the finished charcoal briquette is very hard and strong, one person stand on it is no problem.

Parameter of hydraulic briquette machine:

| Type | Power | Punching time | Weight | Capacity |

| Hydraulic-48 | 15 + 2.2 + 0.75 kw | 4-6 times/min | 1.8 t | 300-400 kg/hour |

Raw materials :

(1) raw material: different kinds powder materials.

(2) raw material diameter: less than 3mm.

(3) raw material moisture: 8%-15%

(4) binder formula: we have different kinds binder formulas, we will add binder according to your raw material.

(5) other technique: we also can offer water-proof formula and instant ignite(combustion-supporting) to our customers for free.

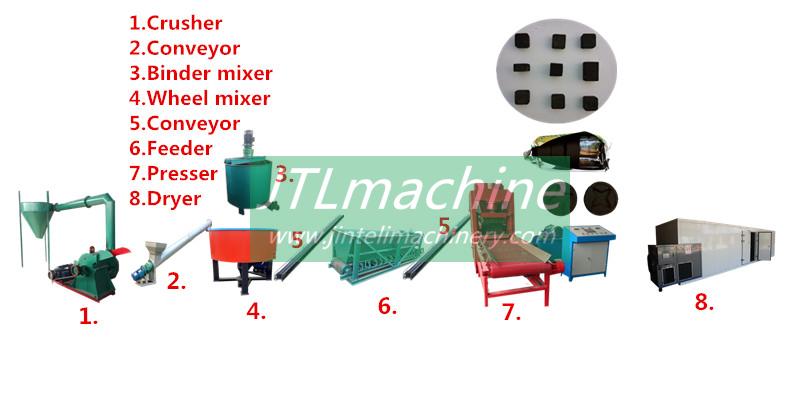

The whole production line:

- Crushing: if raw materials are large charcoal or small pieces (larger than 3mm), you need crush them into powder firstly

- Mixing: it needs mix liquid binder and charcoal powder together

- Shaping: our hydraulic punch briquette machine can press charcoal powder into different shapes and sizes

- Drying: finished charcoal briquettes have about 18% moisture, so it needs be drying in dryer, so they can be stored, or packed directly.

Customers from different countries:

When customers arrive our factory, we will test machine for them face to face, so that they can know well our product quality clearly.For some customers, if it’s not convenient to visit our factory, we will send some samples to them, if they are interested in.Surely, the best way is coming here check product quality by yourself, usually we believe what we see.

Packing and delivery:

In free fumigation wooden case with steel frame,then put into the container, or bulk in the container, fixed with wooden strips.

There are some freight forwarding with long term cooperation with us, not only high efficient and high speed, but also can offer most economical price to you.