Introduction:

Biomass briquette machine is a kind of environment protect and energy -saving product .This new screw type biomass briquette machine can change the mold more easily ,and more durable .It use screw working principle to squeeze straw powder or other biomass powder whose diameter less than 3 mm into biomass briquettes.

Suitable raw material :

Raw materials are some agro-forestry wastes, biomass wastes and some organic powder machines, such as sawdust, crop straw, wood branches, rice husk, sugar bagasse, bamboo powder, peanut shell, coconut shell,sunflower shell, cotton stalks, corn stalks, sesame straw, corncob and so on.The raw materials size should be below 3mm, and the moisture should be 8%-10%.

Working principle :

1.Screw working principle;propeller provides impetus pressure to force powder move towards the exit.

2.High temperature high pressure shaping principle:three heating rings provide high temperature,meanwhile,the inner shaping drum provide high pressure.

It using screw propeller’s high pressure and heating ring’s high temperature, compress and extrude loose biomass into high density and small volume wood briquettes.

Final product of compressed wood log briquette machine:

Finished log shape and size:

Hollow quadrangular, hexagonal or cylindrical 50-80 mm diameter rod shape, with 15-20 mm hole in it.

It can used as fuel, boiler heating, cooking, and other field. Especially after carbonized, not only it has long burning time, but also smokeless, smelless, clean, widely used in barbecue market.

Main components of biomass briquette machine :

The parts of screw type biomass briquette making machine are inner shaping drum,propeller,outer shaping drum, heating rings, motor power, feeding port, etc. The propeller is used to push wood chip powder into inner shaping drum and outer shaping drum,at the same time, tremendous pressure squeeze fine wood chip powder into certain shape wood stick briquette, by the way, heating rings can make about 380 centigrade to shape biomass rods finally into high density high hardness wood briquette.

Main spare parts of biomass briquette machine :

a) Heating rings:

Each biomass briquette machine has 3 heating rings. these heating rings are used to provide high temperature for biomass powder.

b) Propeller:

There is one propeller in one set biomass briquette machine. The propeller is used to push fine biomass powder towards the inner shaping drum.(biomass briquette making machine )

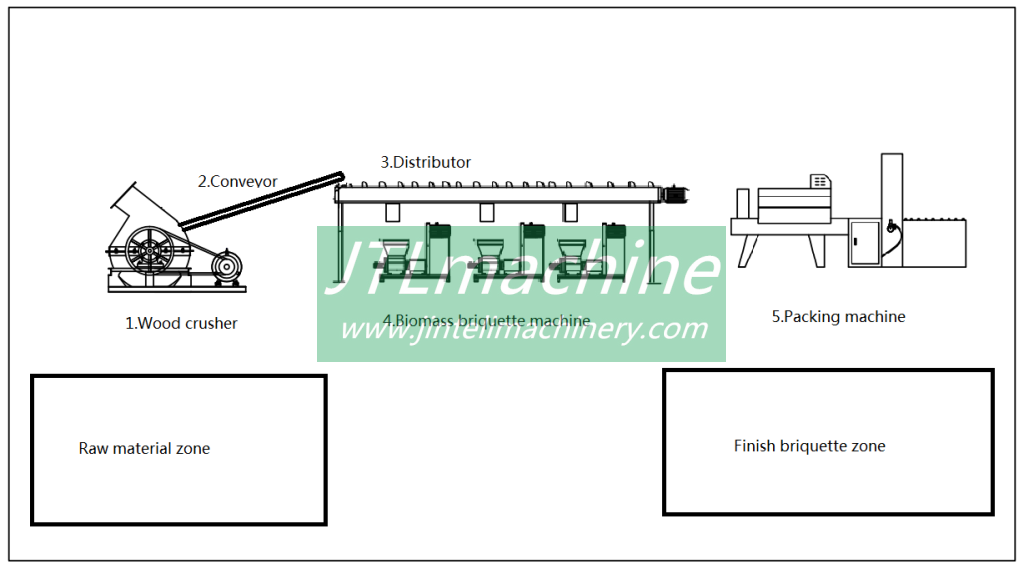

The whole product line:

1) Wood crusher:Wood crusher is used to crush straw,leaves, fruit shell, tree branches, wood sawdust, wood chips, etc. into fine powder whose dimension less than 3mm.

2)Airflow dryer or rotary dryer: Before fine biomass powder being shaped into biomass briquette,we need to make sure the powder’s humidity less than 10%. Because if the humidity more than 10%,it will make a lot of smoke and the final biomass briquette can not in high density.

3) Wood briquette machine: Use biomass briquette machine to shape biomass powder into briquettes.

4)Carbonization furnace: If you want to make briquette charcoal ,we need carbonization furnace to burn biomass briquettes into charcoal briquettes.

About packing and delivery :

About packaging, we can offer free fumigation wooden case with steel frame, which is very strong, not only can protect machine from damage, but also avoid checking when exporting.For multiple machines, or production line, it’s better to loaded in standard container 20GP, 40GP, usually it needs wrapped with plasitc firstly, then loaded in container. About shipping, we can offer EXW, FOB and CIF terms.