Product description:

1) Frame: The whole frame includes cast iron bedplate, motor base. The frame is the main skeleton entity.

2) Transmission part: This part consists of motor power, belt gear, gear, transmission shaft.

3) Feeding part: This part consists of moving shaft, hopper, mixer, turnplate. Under the help of mixer and turnplate, coal powder will be feed into the shaping drum.

4) Punching part: Punching part is the most important in the whole honeycomb coal briquette machine, it consists of four slide bars, beam, punch, punch seat, moving pressure plate, spring,etc. When honeycomb coal briquette machine working, two gears moving and push upper punching part punching down though pull rod, meanwhile, movale plate moving up and makes spring shorter, this makes coal powder into briquettes shape.

5) Conveyor part: This part consists of transmission rack, belt pulley, holder.

Characteristics :

1) All spare parts of punch type coal briquette machine are made by ourselves.

2) All connecting parts we use cooper spirals instead of iron spirals to make the whole honeycomb coal briquette machine has longer service time.

3) All parts made by advanced technology, we use wire-cutting technology rather than normal cutting technology.

4) Our punch type coal briquette machine has position-guide angle to protect punching parts.

5) Shaping mold can be customized according to your demands.

Advantages:

(1) Positioning system: distinctive positioning system, can position accurately once.

(2) Copper sheathing: Copper is more durable than other materials, so every coal briquette machine use copper to lengthen machine service time.

(3) Customized service: Molds can be customized according to customers special demands.

(4) Strict quality control system: We have strict quality control system from purchasing to manufacturing, from a small screw to machine materials.

(5) Enough parts supply: Our spare parts are manufactured standardized in batch, so you can get them easily and convenient in future.

(6)Factory but not trading company: We are a 30 years factory, but not trading company, all machine are designed and manufactured by ourselves, so we can guarantee product quality better.

Molds of briquette machine:

Molds are multifarious(below are some of them), also can be customized according to your demands. Besides, molds can be changed easily. Changed into different molds, you can get different products.

As the picture show, every machine has two punching needles, which can press twice, so the finished briquettes have higher density. Also another function of the second punching needle is adding combusion improver just on the surface. With combusion improver, the charcoal or coal briquettes can be instant ignited.

As the picture show, every machine has two punching needles, which can press twice, so the finished briquettes have higher density. Also another function of the second punching needle is adding combusion improver just on the surface. With combusion improver, the charcoal or coal briquettes can be instant ignited.

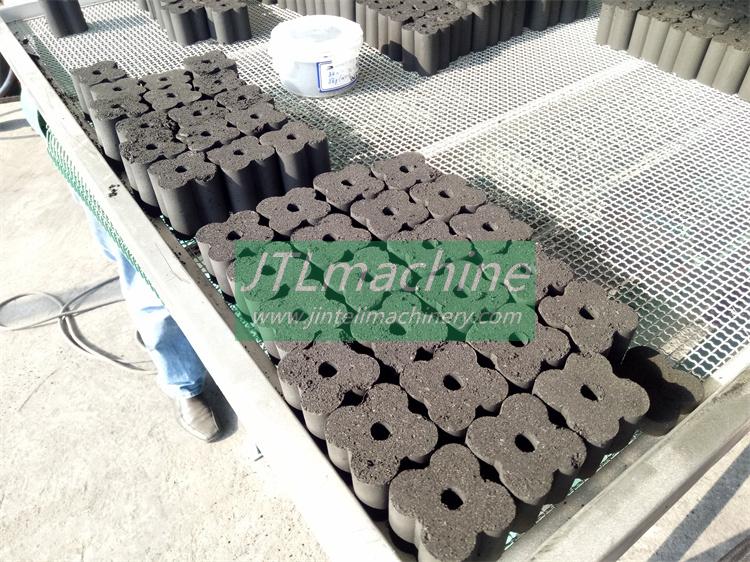

Finish briquette :

It used in stove for cooking, bbq, warming,etc. The final briquette are high density, high hardness.Because we can customize molds shape and size depending on customers demand, so different briquettes can be satisfied. For example, honeycomb shape, hexagonal shape, cylinder shape, quadrilateral shape, etc.

Shape: Round shape coal briquette with several holes(Diameter between 140-300mm) Cylinder shape with a hole( diameter 50mm with a 15mm hole is the most popular size) Plum-blossom shape with hole, square shape with several holes( the length are customized),hexagonal shape with a hole, rectangle shape, etc.

Size: The diameter or length is 45mm-300mm.

Density: The density of coal briquettes can be adjusted according your demands by changing the upper punching part.

Burning time: The burning time is about 4-5 hours per small piece.

Packing and delivery :

We will suggest most economical and safe shipping terms to you:

If single machine, wrapped with plastic firstly, then put into free fumigation wooden case with steel frame;

If multiple machine or whole machine line, wrapped with plastic firstly, then load in standard container, 20GP, 40GP, 40HQ, etc.

There are some freight forwarding with long term cooperation with us, not only high efficient and quick speed, but also can offer most economical price to you.