Table of Contents

Best Chinese machine for making bbq charcoal: Top Features and Benefits

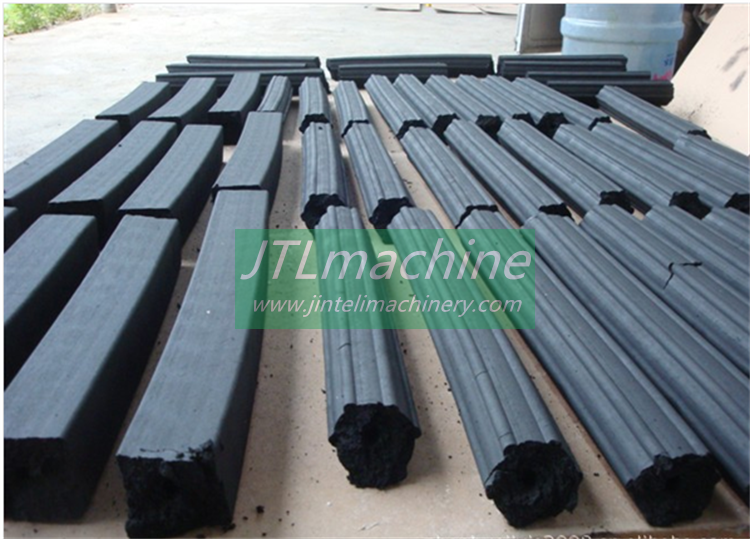

When considering the best Chinese machines for making BBQ charcoal, it is essential to examine the top features and benefits that distinguish them in the market. These machines have gained significant attention for their efficiency, innovation, and cost-effectiveness. For those in the charcoal production industry, understanding these key aspects can provide a clear advantage in selecting the right equipment to meet their needs. One of the primary features of Chinese machines for making BBQ charcoal is their advanced technology. Many of these machines utilize high-temperature pyrolysis processes to convert raw materials like wood, coconut shells, and agricultural waste into high-quality charcoal. This method not only ensures a high carbon content in the final product but also produces charcoal that burns longer and more evenly, which is crucial for BBQ applications. Additionally, the use of automated controls and computerized systems enhances the precision and consistency of the production process, leading to a superior end product. Another notable benefit is the energy efficiency of these machines. With increasing global emphasis on sustainability and reducing carbon footprints, Chinese manufacturers have responded by developing machines that consume less energy and produce minimal waste. Many of these machines are equipped with energy-saving features such as heat recovery systems, which capture and reuse heat generated during the production process. This not only reduces operational costs but also aligns with environmentally conscious business practices, making these machines an attractive option for eco-friendly manufacturers.Finding the Lowest Price Manufacturer for Charcoal Machine Lines in China

When seeking the lowest price manufacturer for charcoal machine lines in China, it is essential to consider several critical factors to ensure a balance between cost and quality. China, known for its vast manufacturing capabilities and competitive pricing, offers numerous options for sourcing charcoal machine lines that produce BBQ charcoal efficiently. However, finding a manufacturer that offers the best price without compromising on the machine’s quality and performance requires thorough research and strategic evaluation. First, it’s crucial to understand the specific requirements of a charcoal machine line. These machines typically include various components such as crushers, dryers, briquette machines, and carbonization furnaces. Each component plays a vital role in the overall efficiency and output of the charcoal production process. Therefore, when evaluating manufacturers, one should assess the technical specifications, build quality, and integration capabilities of these components. Manufacturers that provide detailed information about their products’ features and operational parameters demonstrate transparency and reliability, which are key indicators of a reputable supplier. Next, it is advisable to conduct a comparative analysis of several manufacturers. This involves gathering quotations and detailed product descriptions from multiple sources. Websites, industry forums, and trade shows can be valuable resources for identifying potential suppliers. Comparing prices is essential, but it should be done in conjunction with evaluating the quality of materials used, the durability of the machines, and the after-sales support provided. A lower initial cost may sometimes lead to higher long-term expenses if the machines require frequent maintenance or have shorter lifespans.

Next, it is advisable to conduct a comparative analysis of several manufacturers. This involves gathering quotations and detailed product descriptions from multiple sources. Websites, industry forums, and trade shows can be valuable resources for identifying potential suppliers. Comparing prices is essential, but it should be done in conjunction with evaluating the quality of materials used, the durability of the machines, and the after-sales support provided. A lower initial cost may sometimes lead to higher long-term expenses if the machines require frequent maintenance or have shorter lifespans.

Another important aspect to consider is the manufacturer’s experience and reputation in the industry. Manufacturers with a long history of producing charcoal machine lines are more likely to have refined their processes and technology, resulting in more reliable and efficient machines. Customer reviews and testimonials can provide insights into the manufacturer’s reliability and customer service. Additionally, companies that export their products globally often adhere to higher standards and regulations, which can be a testament to their product quality.

Engaging directly with manufacturers can also provide valuable insights. Visiting factories, if feasible, allows potential buyers to witness the manufacturing process firsthand, assess the working conditions, and evaluate the quality control measures in place. For those unable to visit in person, video calls and virtual tours can serve as effective alternatives. Direct communication with manufacturers can also help in negotiating prices and obtaining customized solutions that fit specific production needs.

Moreover, considering the logistical aspects is vital. China’s extensive manufacturing landscape means that factories are spread across various regions, each with different logistical advantages. Factories located near major ports or in regions with well-developed transportation infrastructure can offer significant savings in shipping costs and delivery times. Additionally, understanding the export procedures and ensuring that the manufacturer has experience with international shipping can prevent potential delays and additional costs.

In conclusion, finding the lowest price manufacturer for charcoal machine lines in China involves a comprehensive approach that goes beyond just comparing prices. Evaluating the technical specifications, quality, manufacturer’s experience, and logistical considerations are all critical components of making an informed decision. By taking these factors into account, buyers can secure high-quality charcoal machine lines that offer excellent value and contribute to efficient and cost-effective BBQ charcoal production.

Another important aspect to consider is the manufacturer’s experience and reputation in the industry. Manufacturers with a long history of producing charcoal machine lines are more likely to have refined their processes and technology, resulting in more reliable and efficient machines. Customer reviews and testimonials can provide insights into the manufacturer’s reliability and customer service. Additionally, companies that export their products globally often adhere to higher standards and regulations, which can be a testament to their product quality.

Engaging directly with manufacturers can also provide valuable insights. Visiting factories, if feasible, allows potential buyers to witness the manufacturing process firsthand, assess the working conditions, and evaluate the quality control measures in place. For those unable to visit in person, video calls and virtual tours can serve as effective alternatives. Direct communication with manufacturers can also help in negotiating prices and obtaining customized solutions that fit specific production needs.

Moreover, considering the logistical aspects is vital. China’s extensive manufacturing landscape means that factories are spread across various regions, each with different logistical advantages. Factories located near major ports or in regions with well-developed transportation infrastructure can offer significant savings in shipping costs and delivery times. Additionally, understanding the export procedures and ensuring that the manufacturer has experience with international shipping can prevent potential delays and additional costs.

In conclusion, finding the lowest price manufacturer for charcoal machine lines in China involves a comprehensive approach that goes beyond just comparing prices. Evaluating the technical specifications, quality, manufacturer’s experience, and logistical considerations are all critical components of making an informed decision. By taking these factors into account, buyers can secure high-quality charcoal machine lines that offer excellent value and contribute to efficient and cost-effective BBQ charcoal production.